Exponential Technologies revolutionary R&D data science platform allows you to go from idea to product faster than ever. Reduce real-life experiments, iterate faster and get the most out of your data.

“The xT team is a pleasure to work with – extremely intelligent, dedicated, and accommodating. We look forward to a long- term relationship where we utilize their software.”

xT SAAM streamlines and intelligently guides you through your product development. Collect and analyse clean & tidy data – allowing you to make better and faster decisions.

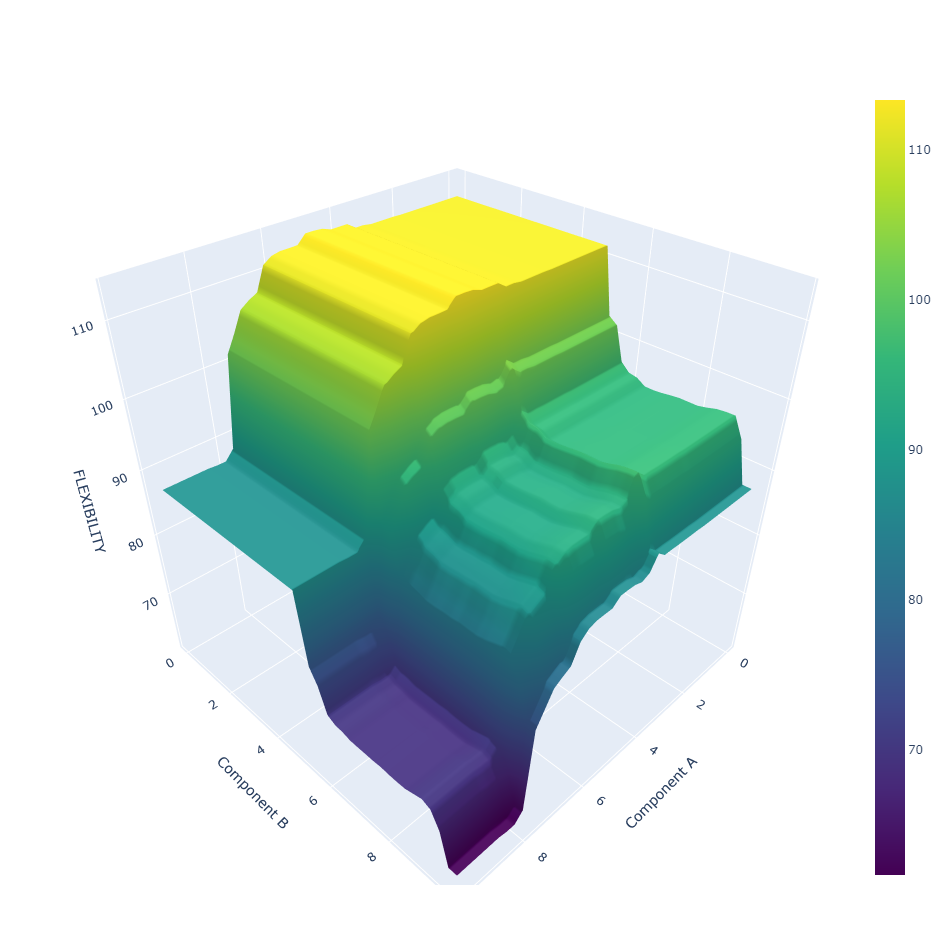

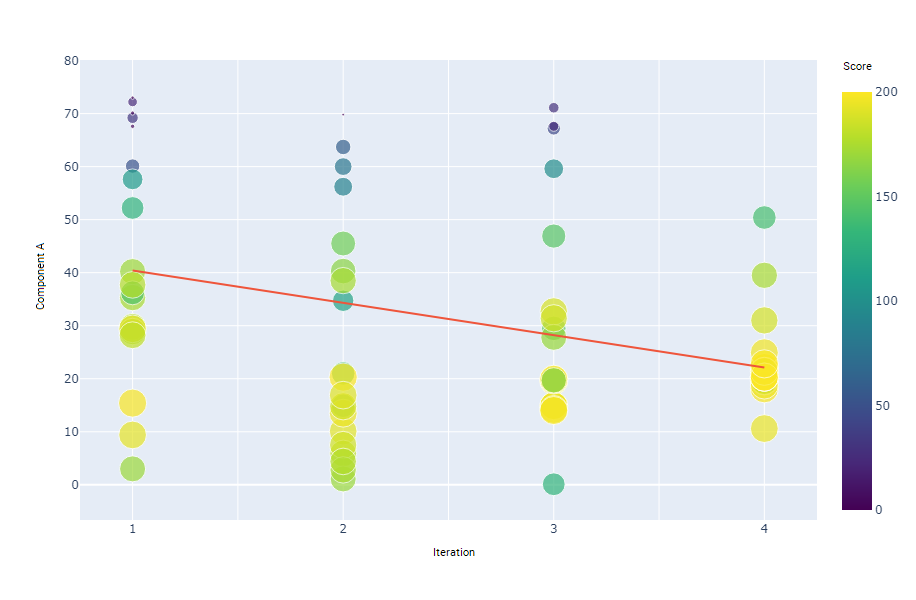

Replace your design of experiments with AI & ML assisted development. xT SAAM best-in-class algorithms require significantly less data than other methods.

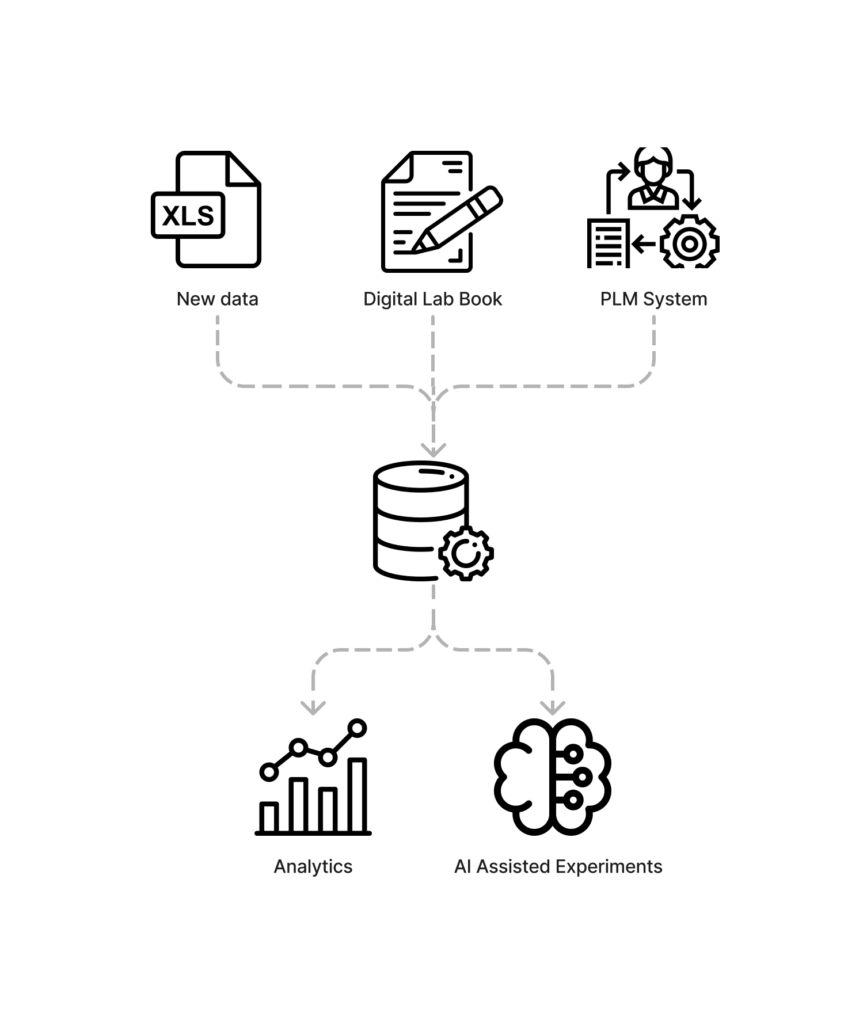

Keep your experimental data in one place. Connect to other systems to take into account all relevant data in your R&D.

With all your data in one place, SAAM can turn it into insights. Leverage visualizations, custom reports, and predictive models to accelerate your innovation.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |