Additive manufacturing

Small changes, big impact

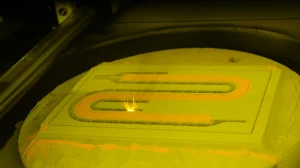

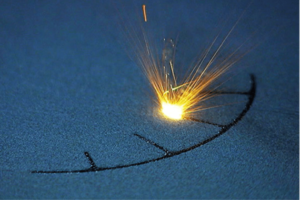

In classical manufacturing there are appr. 10 000 different materials available. However, in additive manufacturing there are currently only a few hundred available. The reason for this is that in additive manufacturing the material properties can be altered substantially by changing the printer parameters. This is one of the huge benefits of additive manufacturing, as material properties can be adjusted to fit specific use cases during manufacturing. On the other hand, this makes also the development of new materials and printer parameters extremely time and cost intensive.

Main benefits

xT SAAM helps:

- Reduce go-to-market time and costs for new materials

- Develop new materials specifically designed for AM applications

- Develop printer parameters for existing and new materials

xT SAAM works for any printer type, materials or processing type and the user doesn’t require statistical or DoE expertise.

Field-Tested

We could show so far amazing results in metal powder bed fusion systems from EOS and SLM Solutions, FFF printers of all different types and materials and in the development of SLA resins together with process parameters with our partner Evonik Industries.